- Hoge kwaliteit en uitgebreide service

- Al meer dan 100 jaar een begrip

- Een breed assortiment

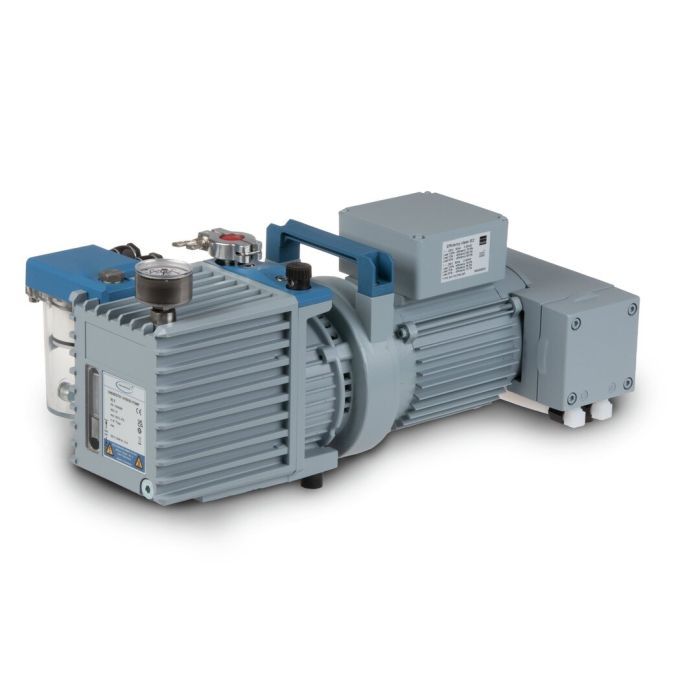

Combinatie van een dubbeltraps draaischuifpomp met een dubbeltraps membraanpomp

Ideaal geschikt voor vriesdrogers

Eindvacum: 2 x 10-3 mbar

Pompsnelheid: 5,9 m3/h

Vermogen: 370 Watt

Afmetingen (lxbxh): 510 x 305 x 230 mm

Gewicht: 24,2 kg

Aansluiting inlaat: kleinflens aansluiting DN16

Aansluiting uitlaat: slangaansluiting Ø 10 mm

- Vacuubrand RC5

| Merk | Vacuubrand |

|---|

Vacuubrand RC6 Chemie-Hybride-vacuümpomp

- Ideaal geschikt voor vriesdrogers van bijvoorbeeld Christ, Labconco of Scanlab.

- Ideaal geschikt voor Thermo Speedvac bij het werken met DMSO.

- Aanzienlijk verminderd olieverversingsintervallen en onderhoud.

- Met ingebouwde olienevelfilter.

- Combinatie van een dubbeltraps draaischuifpomp met een dubbeltraps membraanpomp

- De draaischuifpomp is de actieve pomp en de membraanpomp wordt ingezet om de drukzijde van de pomp op vacuüm te houden om condensatie in de pomp te verhinderen, waardoor gassen de pomp ook in de gasfase verlaten.

- Hierdoor ontstaat een sterk verbeterde chemische bestendigheid van de actieve pomp.

- De RC 6 is een goede keuze indien een chemisch bestendige membraanpomp niet inzetbaar is vanwege een te gering eindvacuüm.

- Compacte en geruisarme pomp met hoge doorstroomsnelheid, tot dichtbij het bereiken van het eindvacuüm.

- Zeer hoge waterdamp verdraagbaarheid.

- Vacuümdicht bij uitschakelen of stroomuitval.

- Makkelijk uitvoeren van onderhoud mogelijk door telescopische opbouw.

Meer informatie van Vacuubrand website

The RC 6 chemistry-HYBRID pump is a combination of a two-stage rotary vane pump and a two-stage chemistry diaphragm pump for optimized corrosion resistance. The diaphragm pump maintains the oil reservoir under vacuum in order to keep the partial pressures of solvent vapors at levels below their condensation points and to reduce largely the concentration of oxygen and corrosive gases. Therefore the RC 6 chemistry-HYBRID pump has a much higher solvent vapor pumping capability and resistance to aggressive gases than conventional rotary vane pumps.

Performance features

- reduced internal corrosion, even when working with corrosive vapors

- oil changes typically reduced 90% or more compared with rotary vane pumps alone

- excellent environmental friendliness due to efficient solvent recovery (accessory kit PC 8 with emission condenser; or as pumping unit PC 8)

- most economical solution: In practical operation a cold trap is often no longer necessary. For large amounts of vapors a pumping unit PC 3 / RC 6 with cold trap at the inlet is available

- ease of maintenance due to telescopic design

Technical data

| Technical data | Unit | RC 6 |

|---|---|---|

| Number of stages | 2 + 2 | |

| Max. pumping speed at 50/60 Hz | m3/h | 5.9 / 6.9 |

| Max. pumping speed at 50/60 Hz | cfm | 3.5 / 4.1 |

| Ultimate partial vacuum (abs.) | mbar | 4 x 10-4 |

| Ultimate vacuum (abs.) | mbar/torr | 2 x 10-3 / 1.5 x 10-3 |

| Ultim. vac. (abs.) with gas ballast | mbar/torr | 1 x 10-2 / 0.75 x 10-2 |

| Water vapor tolerance with gas ballast | mbar | >> 40 mbar |

| Ambient temperature range (operation) | °C | 12 - 40 |

| Ambient temperature range (storage) | °C | -10 - 60 |

| Oil capacity (B-Oil) min./max. | l | 0.34 / 0.53 |

| Max. back pressure (abs.) | bar | 1.1 |

| Inlet connection | Small flange KF DN 16 | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Rated motor power | kW | 0.37 |

| Rated motor speed at 50/60 Hz | min-1 | 1500/1800 |

| Degree of protection | IP 40 | |

| Dimensions (L x W x H) | mm | 510 x 305 x 230 |

| Weight | kg | 24.2 |

| Noise level at 50 Hz, typ. | dBA | 50 |

| Items supplied | Pump completely mounted, ready for use after oil filling (bottle 0.5 l enclosed), with manual. | |

| Accessories | PTFE tubing KF DN 16 (1000 mm: 686031) Stainless steel tubing KF DN 16 (1000 mm: 673336) Kit PC 8 with emission condenser (699949) Filter element oil mist filter RC (640187) Package fine vacuum control KF DN 16 (635983) Rubber vacuum tubing DN 8 mm (686001) Small flange KF DN 16 with hose nozzle DN 8-10 mm (662806) |

Chemistry-HYBRID-pumps

The RC 6 chemistry-HYBRID pump is a combination of a two-stage rotary vane pump and a two-stage chemistry diaphragm pump for optimized corrosion resistance. The diaphragm pump maintains the oil reservoir under vacuum in order to keep the partial pressures of solvent vapors at levels below their condensation points and to reduce largely the concentration of oxygen and corrosive gases. Therefore the RC 6 chemistry-HYBRID pump has a much higher solvent vapor pumping capability and resistance to aggressive gases than conventional rotary vane pumps.

PERFORMANCE FEATURES

- reduced internal corrosion, even when working with corrosive vapors

- oil changes typically reduced 90% or more compared with rotary vane pumps alone

- excellent environmental friendliness due to efficient solvent recovery (accessory kit PC 8 with emission condenser; or as pumping unit PC 8)

- most economical solution: In practical operation a cold trap is often no longer necessary. For large amounts of vapors a pumping unit PC 3 / RC 6 with cold trap at the inlet is available

- ease of maintenance due to telescopic design

THERMODYNAMIC FUNCTIONAL PRINCIPLE OF THE CHEMISTRY-HYBRID PUMP

1 - Vapor is aspirated at low pressure and ambient temperature.

2 - Vapor is heated to approx. 60°C by heat exchange and compression within pump.

C - Condensation problem with "normal" rotary-vane pumps: On the way to atmospheric pressure, the saturation vapor pressure (transition to liquid state) is reached inside the oil-filled section. Result: Condensation and corrosion inside the pump; contamination of the oil.

3 - Chemistry-HYBRID Pump: The chemistry diaphragm pump evacuates the vapors from the oil reservoir of the rotary-vane pump. Under intended operating conditions, no condensation takes place inside the oil-filled part and, in particular, within the oil reservoir. (Any condensation taking place inside the oil-free diaphragm pump is much less problematic.) Less condensation means less corrosion and cleaner oil for longer life. For example, in the case of acid vapors, the evacuation of the oil reservoir to 20 mbar reduces corrosion by a factor of about 50!